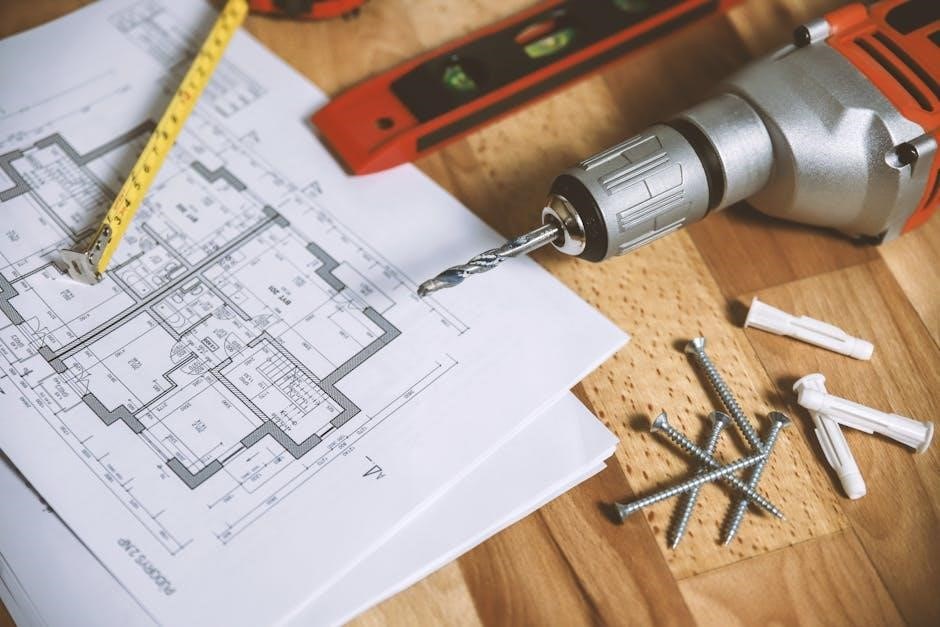

A drill tap guide is a versatile tool designed to enhance precision and consistency in machining and woodworking projects. It provides a stable platform for accurate hole drilling and thread tapping‚ ensuring professional results every time.

By streamlining the drilling and tapping process‚ it reduces errors and saves time‚ making it an essential tool for both professionals and DIY enthusiasts alike. Versatility and ease of use make it a must-have for any workshop.

Overview of Drill Tap Guide

A drill tap guide is a specialized tool designed to assist in precise drilling and tapping operations. It ensures accurate alignment between drill bits and taps‚ minimizing errors and improving workflow efficiency. Whether for machining metals or woodworking‚ this guide stabilizes the tools‚ preventing misalignment and vibration. Its robust construction and adjustable features make it adaptable to various projects‚ ensuring consistent results.

Key features often include precise alignment mechanisms‚ durable materials‚ and compatibility with different drill bits and taps. This tool is invaluable for professionals and hobbyists‚ offering a reliable solution for creating threaded holes efficiently. Its versatility and ease of use make it a cornerstone in many workshops‚ enhancing both productivity and precision.

Importance of Drill Tap Guide in Machining and Woodworking

The drill tap guide plays a crucial role in ensuring precision and consistency in both machining and woodworking. By providing a stable platform for drilling and tapping‚ it helps create accurate threaded holes‚ which are essential for secure fastening. This tool minimizes errors‚ such as misaligned holes or damaged threads‚ which can lead to costly rework or material waste. In woodworking‚ it enhances the quality of joints and fittings‚ while in machining‚ it ensures the integrity of mechanical components. Its ability to streamline the process saves time and increases productivity‚ making it indispensable for professionals and hobbyists alike. Precision and efficiency are key to achieving professional results‚ and the drill tap guide delivers both.

Additionally‚ the guide reduces the risk of tool damage and prolongs the lifespan of drill bits and taps. Its versatility allows it to work with various materials‚ including metals‚ wood‚ and plastics‚ making it a valuable asset for diverse projects. By eliminating guesswork and ensuring uniform results‚ the drill tap guide elevates the quality of craftsmanship in both industries. Its importance lies in its ability to simplify complex tasks while maintaining high standards of accuracy and reliability; This makes it a must-have tool for anyone seeking to achieve professional-grade outcomes in machining and woodworking.

Choosing the Right Tools for Drilling and Tapping

Selecting the right tools is crucial for efficient and precise drilling and tapping. Ensure compatibility with your material and project requirements to achieve optimal results and longevity.

Selecting the Correct Drill Bits and Taps

Selecting the correct drill bits and taps is essential for achieving precise and professional results in drilling and tapping operations. The choice of tools depends on the material being worked on‚ such as metal‚ wood‚ or plastic‚ as well as the desired hole size and type. Drill bits vary in diameter‚ flute count‚ and coating‚ while taps differ in pitch‚ thread type‚ and size. Always ensure the drill bit matches the tap size to create proper threads. High-quality tools with appropriate coatings‚ like titanium nitride or carbide‚ enhance durability and performance. Proper selection prevents damage to the workpiece and tools‚ ensuring smooth and accurate operations.

Understanding Drill Bit and Tap Sizes‚ Materials‚ and Coatings

Drill bit and tap sizes are critical for precise hole drilling and threading. Bits are measured by diameter‚ while taps are categorized by pitch and thread type. Materials like high-speed steel (HSS)‚ carbide‚ and titanium nitride offer varying levels of durability and wear resistance. Coatings‚ such as titanium nitride‚ enhance tool life by reducing friction and preventing overheating. For woodworking‚ spade or forstner bits are ideal‚ while metalworking often requires twist or stub drills. Taps are available in different flavors‚ such as hand taps or machine taps‚ each suited for specific applications. Proper material and coating selection ensures optimal performance and longevity of tools. Always match tool material to the workpiece for best results.

Key Features to Consider When Purchasing Drill Taps

When selecting drill taps‚ prioritize features like durability‚ precision‚ and compatibility. Look for high-quality materials‚ such as hardened steel or carbide‚ to ensure longevity. Consider the shank type‚ as a sturdy shank reduces breakage risk. Thread quality and pitch accuracy are crucial for smooth tapping. Check compatibility with various materials‚ including metal‚ wood‚ and plastic. Adjustable depth stops and coolant systems enhance control and prevent overheating. Ease of use and alignment features‚ like pilot pins‚ improve accuracy. Storage cases and ergonomic handles are practical additions. Ensure the tool aligns with your project’s specific needs for optimal performance and efficiency.

Step-by-Step Guide to Drilling and Tapping

A drill tap guide simplifies the process by ensuring precise alignment and consistent results. Start by preparing the workpiece‚ then drill pilot holes. Use the guide to maintain accurate depth and alignment during tapping. For manual tapping‚ apply steady pressure and maintain tool control. Power tapping offers speed but requires careful monitoring. Always follow safety guidelines and tool recommendations for optimal outcomes. This method ensures professional-quality results with minimal effort and maximum precision.

Preparing the Workpiece and Tools for Drilling and Tapping

Before drilling and tapping‚ ensure the workpiece is clean and free from debris. Secure it firmly using clamps or a vise to prevent movement during operations. Inspect the drill bits and taps for sharpness and damage‚ as dull tools can lead to inaccurate results. Apply the appropriate lubricant or cutting oil to reduce friction and prevent overheating. Align the drill tap guide with the marked drilling location on the workpiece to ensure precise alignment. Double-check the tool settings and material specifications to avoid errors. Proper preparation ensures a smooth and efficient drilling and tapping process‚ minimizing the risk of damage to both the workpiece and tools.

Aligning the Drill Bit Properly for Accurate Drilling

Proper alignment of the drill bit is crucial for achieving precise and accurate results. Use the drill tap guide to ensure the bit is perfectly centered over the marked drilling location. Double-check the workpiece’s surface for any obstructions or unevenness‚ as this can affect alignment. Position the drill bit perpendicular to the workpiece to avoid angled holes. For added accuracy‚ use a center punch to create a small indentation at the drilling site‚ guiding the bit into place. Secure the workpiece firmly to prevent movement during drilling. Consider using a laser guide or alignment fence for enhanced precision‚ especially in complex projects.

Tapping Process: Manual vs. Power Tapping Techniques

When it comes to tapping‚ the process can be performed manually or using power tools‚ each with its own advantages. Manual tapping offers precise control‚ making it ideal for small-scale projects or delicate materials. It involves using a tap wrench to turn the tap by hand‚ ensuring accuracy and avoiding over-tightening. Power tapping‚ on the other hand‚ is faster and more efficient‚ especially for large-scale operations. It uses drill presses or CNC machines to automate the process‚ reducing human error and increasing productivity. Both methods require proper alignment and consistent pressure to achieve clean‚ precise threads. Choosing the right technique depends on the project’s scope‚ material type‚ and desired outcomes.

Troubleshooting Common Issues in Drilling and Tapping

Common issues in drilling and tapping include misalignment‚ overheating‚ and tool damage. Misalignment can result in crooked holes or uneven threads‚ which can be avoided by using a drill tap guide for stability. Overheating occurs when tools are not properly lubricated or cooled‚ leading to premature wear. Applying cutting fluid or coolant can prevent this. Tool damage often stems from using the wrong tap or drill bit for the material or applying excessive force. Regular tool maintenance and following manufacturer guidelines can mitigate these problems. Addressing these issues ensures smoother operations and extends tool lifespan‚ resulting in higher quality finishes and reduced downtime.

Safety Tips and Best Practices

Always wear safety goggles‚ gloves‚ and proper attire to protect against debris and tool mishaps. Ensure a stable work environment and keep loose clothing tied back for safety.

Essential Safety Equipment for Drilling and Tapping

Safety goggles are crucial to protect eyes from flying debris. Gloves prevent cuts and improve grip‚ while a face mask reduces dust or chemical inhalation. Hearing protection is vital due to loud machinery noises.

Steel-toe shoes safeguard feet from heavy tools or falling objects. Proper work attire‚ including long sleeves and an apron‚ shields skin from sparks and debris. Always secure loose clothing or jewelry to avoid entanglement with tools.

A well-ventilated workspace prevents the buildup of harmful fumes. Ensure all equipment is in good condition‚ and avoid overreach to maintain balance and control during operations.

Preventing Overheating and Tool Damage

Preventing overheating and tool damage requires careful attention to drilling and tapping techniques. Using the correct drill bits and taps for the material ensures efficient cutting and minimizes heat buildup. Always maintain sharp tools‚ as dull edges generate excessive friction and heat.

Apply proper lubrication or coolant to reduce friction and prevent overheating. Avoid applying too much pressure‚ which can overheat tools and damage the workpiece. Regular tool maintenance‚ such as cleaning and sharpening‚ extends their lifespan and performance.

Ensure the workpiece is securely clamped to prevent movement‚ which can cause uneven wear and heat generation. Keep the workshop well-ventilated to dissipate heat effectively. Store tools in a dry‚ cool environment to avoid rust and degradation.

Working in a Stable and Well-Lit Environment

A stable and well-lit workspace is essential for precise drilling and tapping. Ensure your workbench is sturdy and level to prevent vibrations or wobbling during operations. Proper lighting illuminates the workpiece‚ allowing clear visibility of drill bits‚ taps‚ and material surfaces.

Adequate lighting helps identify small details‚ reducing errors and improving accuracy. Use overhead lights or task-specific lamps to maintain even illumination. A clutter-free workspace minimizes distractions and potential accidents‚ ensuring a safer and more efficient workflow.

Regularly clean the area to avoid dust or debris interfering with the process. A well-organized and brightly lit environment enhances focus and precision‚ leading to better results in drilling and tapping tasks.

A drill tap guide is an indispensable tool for achieving precision and efficiency in machining and woodworking. It empowers professionals and hobbyists to produce high-quality results consistently.

Using a drill tap guide offers numerous benefits‚ enhancing accuracy and efficiency in drilling and tapping operations. It ensures precise alignment‚ reducing errors and material waste. The tool promotes consistent results‚ making it ideal for both professionals and hobbyists. By streamlining the process‚ it saves time and effort‚ allowing for faster project completion. Additionally‚ a drill tap guide minimizes the risk of tool damage‚ extending the lifespan of drill bits and taps. Its versatility accommodates various materials and applications‚ providing a reliable solution for diverse projects. Overall‚ it is a cost-effective investment that elevates the quality and professionalism of machining and woodworking tasks.

Encouraging Practice and Skill Development in Drilling and Tapping

Regular practice is essential for mastering drilling and tapping techniques‚ and a drill tap guide is an excellent tool to facilitate skill development. By providing consistent results‚ it helps users build confidence and precision. Beginners can start with soft materials like aluminum or wood to refine their technique without risking damage to expensive tools. As skills improve‚ transitioning to harder materials becomes more manageable. Troubleshooting common issues during practice also enhances problem-solving abilities. Encourage experimenting with different drill bits and taps to understand their mechanics. With patience and consistent practice‚ users can achieve professional-level accuracy‚ making the drill tap guide a valuable aid in their learning journey.